Propulsion & Power

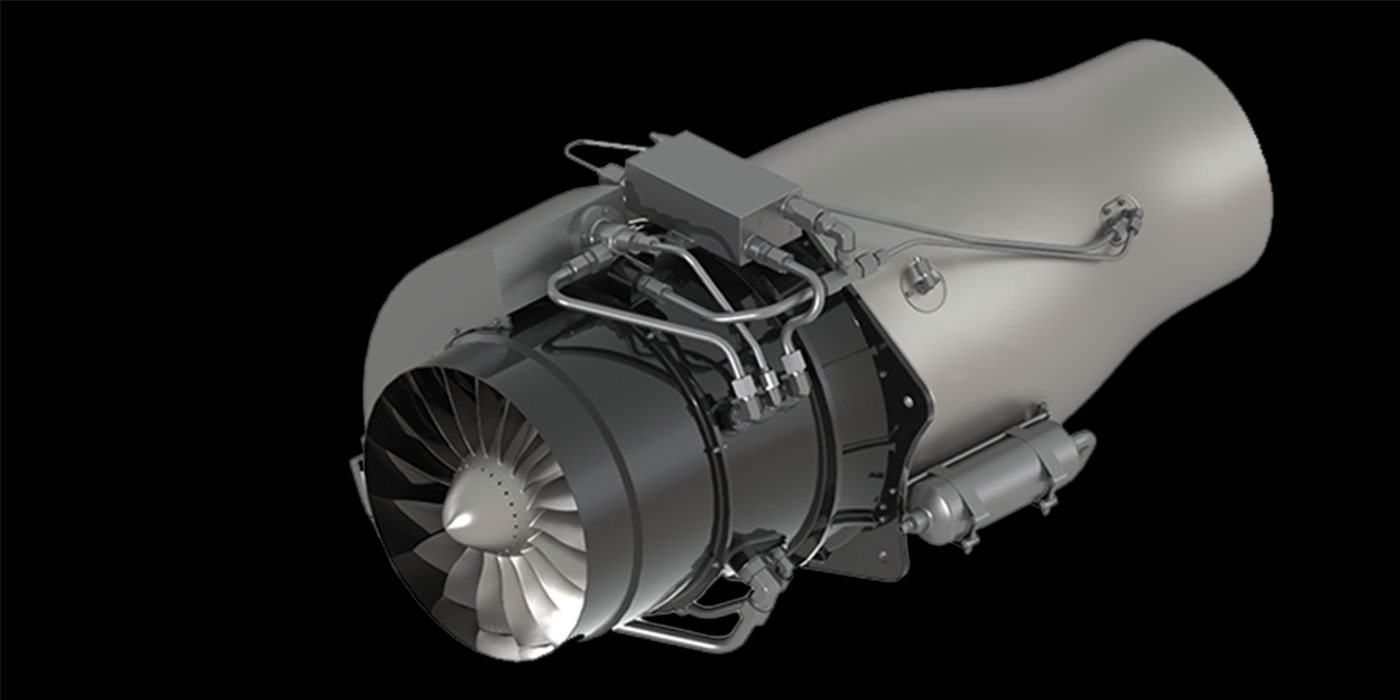

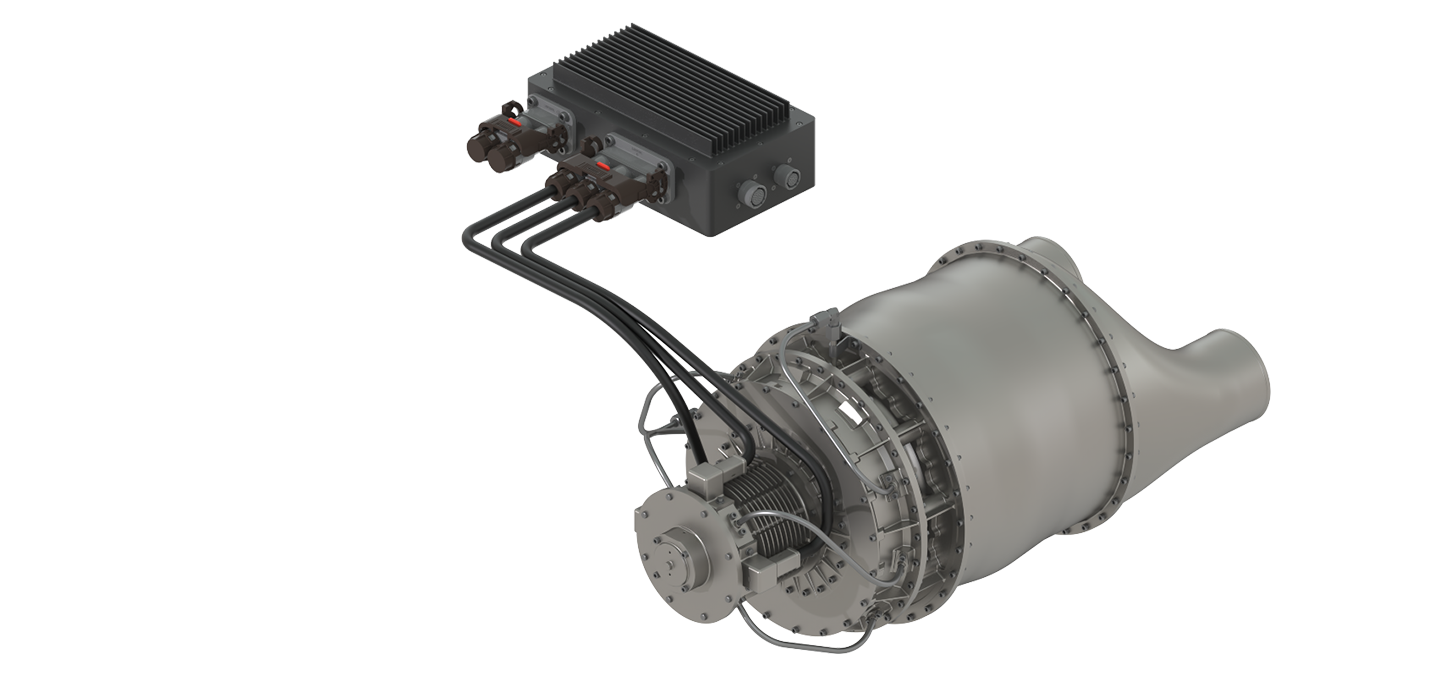

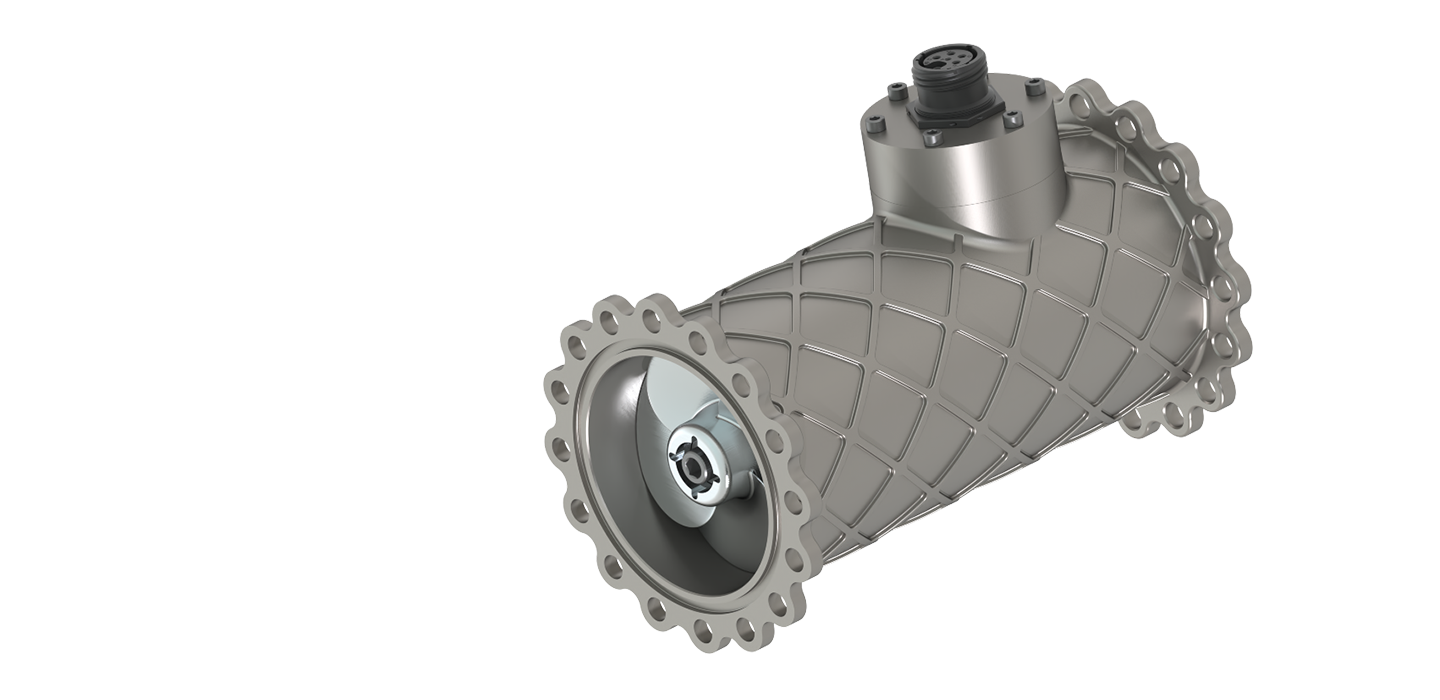

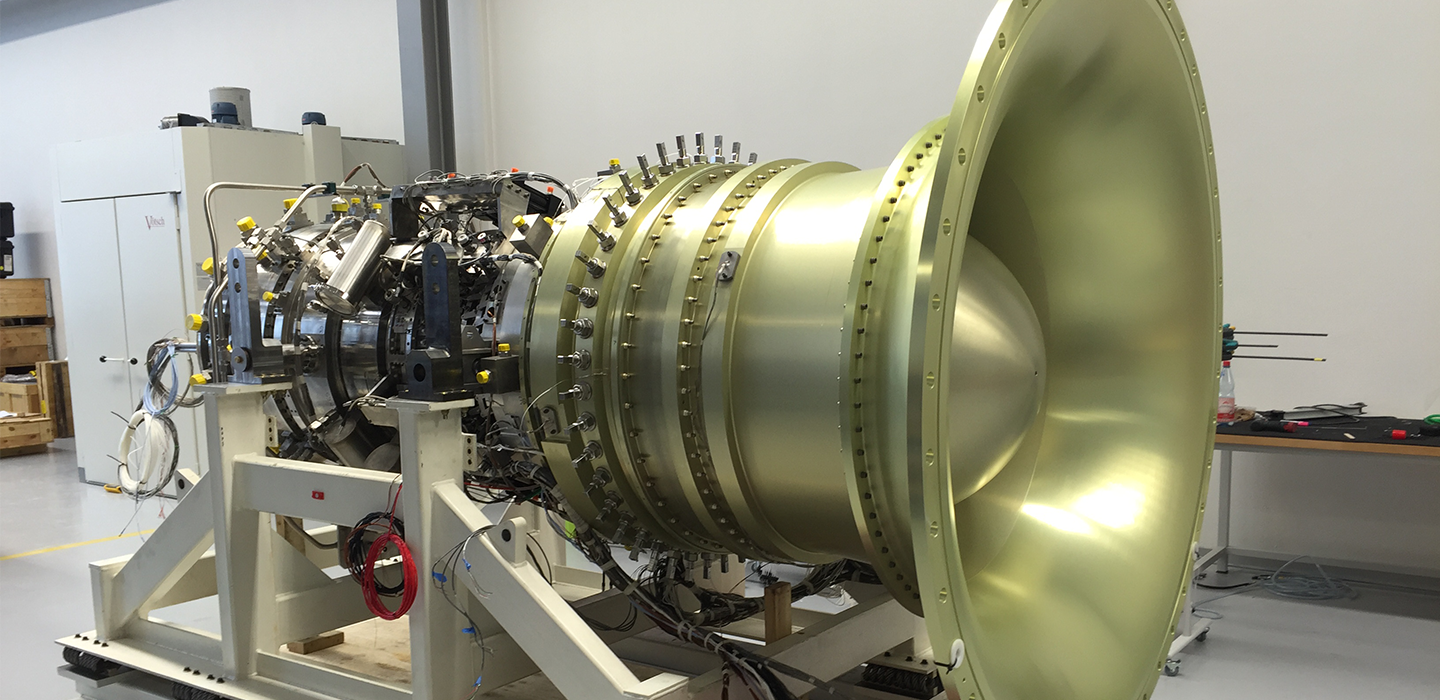

Kratos delivers advanced propulsion and power solutions that enable next-generation defense and aerospace systems. From cost-effective turbojets and turbofans to solid rocket motors, our technologies power tactical platforms, hypersonic vehicles, and strategic weapons. With a focus on performance, scalability, and rapid fielding, Kratos strengthens the U.S. defense industrial base and supports mission success across air, land, sea, and space.

Kratos’ Advantage

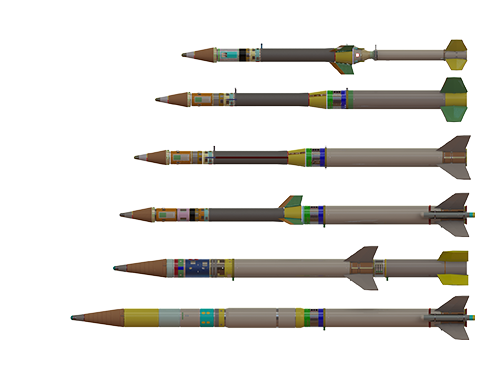

What sets Kratos’ propulsion and power solutions apart is the ability to deliver high-performance systems with unmatched speed, agility, and affordability. Kratos leverages an agile, vertically integrated development model and internally funded innovation to rapidly prototype, test, and scale propulsion solutions. Our portfolio—including GEK-series turbojets and Zeus solid rocket motors—supports a range of applications from attritable unmanned aerial vehicles (UAVs) to hypersonics, ballistics, and strategic weapons, providing the U.S. and its allies with a decisive technological and operational edge.

Join the Kratos Team

Kratos engineers and deploys technology and systems that move national security forward, with the cost, speed, and reliability that make readiness certain.

Join us—explore open roles and apply today.

Contact Us

Have questions or want to learn more about Kratos and our innovative solutions for national security? Fill out this form.

Thank you. We will use your information to respond to your inquiry. We may also contact you about our products and services. You may opt-out at any time using the unsubscribe link in messages you receive from us. You can learn more about how we handle your personal data and your rights by reviewing our privacy policy.